DS Intelligent Tool Management System

Why We Need Tool Management?

What Are the Effects of the System?

What Are the Effects of the System?

- Effectively manage tool inventory.

- Improve tool lifecycle and reduce the risks of collision by correctly controlling and configuring the tools.

- Labor saving for tool management.

- Configure tools via operation plans and integrate Production Management System (PMS).

- Reduce the movement of people for changing tools and then achieve the effect for saving the labor cost.

- Reduce the manual works of tool usage record and analyze tools lifecycle via tool usage record.

Solving the deficiency and difficulty of manpower management for conventional tool.

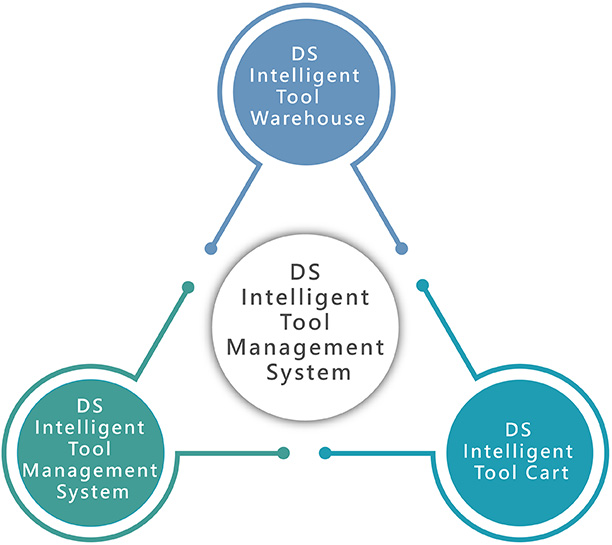

DS Intelligent Tool Warehouse +

DS Intelligent Tool Cart (DITC)+

DS Intelligent Tool Management System

Comprehensive integrated design can helps users select correct tools and record a tool use history in order to enhance production efficiency and to effectively control tool inventory and cost.

Intelligent system integration

Simultaneous monitoring of “DS Intelligent Tool Warehouse”, “DITC Warehouse”, and “Tool Use Status of DITC and CNC machine”, integration of AI technology, and establishment of tool history to calculate optimal recommended tool, and systematically manage tool inventory level and overall processing cost.